Streamlining data collection and precision measurements with Mosaic X and Vulcan Line Tools’ Azmyth platform

“Our services are now able to be completed faster and with higher-quality data. For our customers, this means getting a 5,000-pole city for around $30,000 when before it would've been well over $100,000. And it’s being done in weeks rather than months."

Who is Vulcan Line Tools

Vulcan Line Tools, based in Birmingham, Alabama, specializes in hardware, software, and services for electric utilities and telecom companies. Founded by Zac Young, the company has developed proprietary software called Azmyth, which helps streamline the planning and engineering process for fiber-to-the-premises (FTTP, FTTX, FTTH) projects and infrastructure asset management. The company has become known for its efficient and cost-effective approach to data collection, using its own high-resolution imagery to perform detailed analyses remotely. Their services are aimed at making utility infrastructure projects more efficient by reducing the need for on-site inspections and providing precise measurements directly from captured imagery.

As part of Young’s inspiration for founding Vulcan Line Tools, he recognized a recurring challenge faced by companies trying to install fiber (or any other cables) on utility poles.

"Imagine I'm a fiber company wanting to install fiber on 10,000 power poles across a city like Birmingham. Traditionally, you'd have to send someone out to physically walk to each pole, measuring what's already attached and determining where the new fiber could be safely attached."

The inefficiency of this process was evident, but the need for precise measurement data on these poles still called for high-quality field data. Placing fiber too low could create hazards like clotheslining cars and people while positioning it too high would risk electrocution from power lines.

Unsurprisingly, there are strict regulations that govern attachment heights and safety, known as the NESC clearance standards, which is why measurements need to be as accurate as possible. Zac was confident that he could create a more efficient way of taking these measurements without sacrificing accuracy, improving it even—resulting in the development of Azmyth.

Importance of Distribution Utility Pole Inspection and Asset Management

Distribution utility poles play a crucial role in electric power distribution, as well as in supporting communication networks. These poles, which are primarily made of wood, date back to the late 1800s and became popular because of their cost-effectiveness, availability, and durability. However, due to their exposure to environmental factors such as weather, insects, and decay, they require regular maintenance to remain functional. Ensuring the structural integrity of these poles is vital because failure leads to power outages and safety hazards, significantly impacting daily life and economic activities.

In researching their market, the team at Vulcan Line Tools realized how inefficient the field data collection process for distribution poles currently is. There is a boatload of power poles across the United States (and around the world), so power poles are obviously pretty important because they hold up very dangerous power lines that supply power to the home.

If you’re an internet service provider (ISP), to get high-speed internet in the houses, you also have to attach to the power poles in an area. But electric utilities aren’t inclined to allow just anyone to hook up to their poles. There is an entire industry that focuses on keeping up to date on the currently available real estate on poles to determine what space is still available to run more cables, and here, Vulcan realized just how inefficient current methods are for gathering this data.

As a result, Vulcan Line Tools developed Azmyth and now offers high-quality, accurate imagery and data-driven solutions that enable utility companies to conduct thorough inspections without physically visiting each pole.

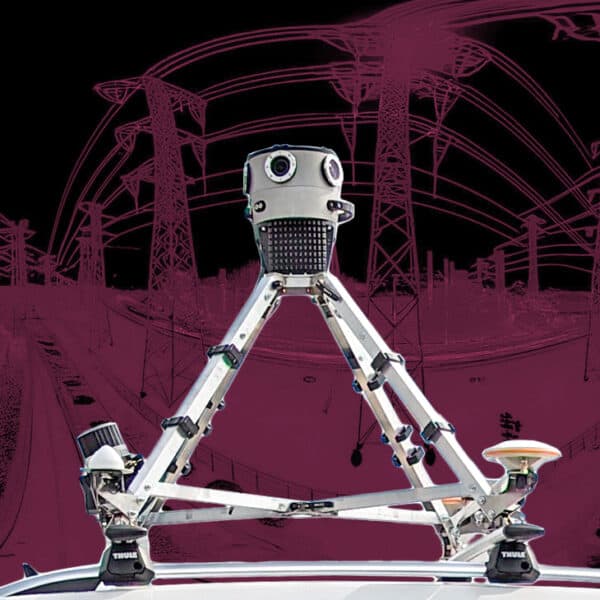

Who is Mosaic – 360º Camera Systems

Mosaic is a company specializing in high-resolution 360-degree camera systems designed for mapping, surveying, and a variety of other applications. Our technology is particularly useful in scenarios requiring precise data collection over large areas, such as infrastructure inspection, urban planning, and utility asset management. By integrating our camera systems into existing workflows, companies can gather detailed imagery quickly, enabling better analysis and more efficient operations. Mosaic’s cameras are known for their ease of use, high image quality, and ability to capture data at highway speeds, which significantly enhances productivity for companies like Vulcan Line Tools.

The Challenges Faced

Before the advent of technologies like 360-degree cameras and remote data collection, the utility pole inspection industry faced significant challenges.

Traditionally, inspecting utility poles requires physical, on-site visits by a small team of field technicians. These technicians have to manually measure attachment heights, span angles, and clearances by using specialized tools. The process is labor-intensive and time-consuming, often requiring companies to send out multiple teams for weeks or months to gather the necessary data for large projects.

Additionally, the cost associated with this manual labor is high, often running into the hundreds of dollars per pole. The complexity increases when poles are located in difficult-to-reach areas, such as urban environments with restricted access or remote, rugged landscapes. This posed a logistical challenge, requiring the coordination of field teams, vehicle access, and sometimes even special permits to enter certain areas.

As Zac Young explains:

“Typically you need a two-man team, walking to each pole to take a few photos and perhaps some measurements and we’re already talking about hundreds of dollars a pole. And essentially it's just a picture and where stuff is out on the pole when it boils down to it.”

Besides being costly and lengthy, the process was also prone to human error. With each technician having to take manual measurements, variations in accuracy were common, leading to inconsistent data that could affect project planning and execution. Worse, this method could take several months to collect data for an entire city or region, causing delays in planning and construction.

The industry’s reliance on manual, on-the-ground inspections meant that utility companies had to factor in not only the cost of labor but also the time delays associated with manual data collection. In a sector where infrastructure demands are high—especially with the expansion of broadband fiber networks—these inefficiencies created bottlenecks. For companies looking to install new fiber or electric lines, every day spent gathering data meant additional project costs and delayed deployments.

In short, the industry’s traditional methods were both costly and inefficient, relying on time-consuming manual labor to gather data that could have been captured much faster with more advanced tools like 360-degree cameras. This is where Vulcan Line Tools’ innovation with the Mosaic X camera system came into play, drastically improving the speed, accuracy, and cost-effectiveness of pole inspections.

Before adopting the Mosaic X camera system, Vulcan Line Tools used a non-Mosaic camera to capture utility pole imagery. However, this camera failed to provide the required accuracy and image quality, leading to inefficiencies in data collection and processing. As the company sought to scale its operations, they needed a more reliable, accurate, and scalable solution.

“Before using Mosaic X, we were using footage from a different 360 camera, and the quality was not up to the standard that we needed to make precise, virtual measurements. Now, we can travel at highway speeds while collecting high quality imagery, and that is crucial for us to maintain our overall value proposition: low-cost, low-time, and highly accurate field inspections.”

The Solution: Mosaic X Camera System

To overcome these challenges, Vulcan Line Tools integrated the Mosaic X camera system into their workflow. Zac explained how they have drastically scaled the capture of data they are now able to manage efficiently.

This decision was driven by the camera’s ability to:

- Capture high-quality images even at highway speeds

- Integrate seamlessly into Vulcan’s proprietary Azmyth software

- Improve efficiency by reducing the time required for field data collection

- Provide precise measurements

“Our services are now able to be completed faster and with higher-quality data.”

The Azmyth Platform: What Vulcan Line Tools Has Built

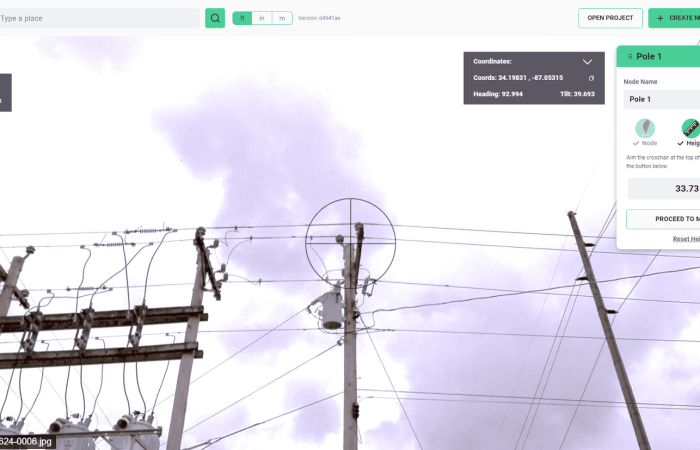

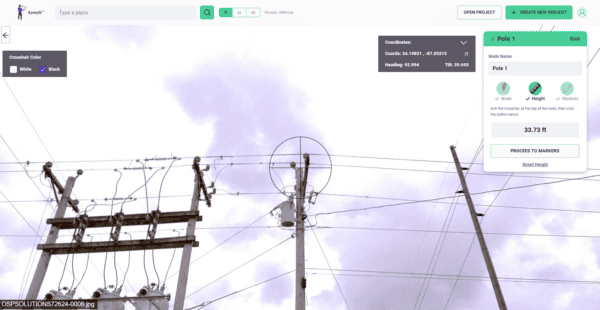

Vulcan Line Tools has developed a proprietary software platform called Azmyth, which leverages high-quality imagery and advanced measurement tools to perform remote utility pole inspections and asset management. The primary focus is on measuring attachment heights, clearances, and other critical dimensions on wooden utility poles used by electrical and communication companies.

“We use the Mosaic X camera system to collect imagery for our proprietary software, Azmyth. Accuracy is crucial for Azmyth, as we use it to deliver precise measurements of distribution power pole heights for electric utilities and communication companies. Using the camera and an external GNSS, we are able to consistently make measurements within two and a half inches of accuracy,” states Zac Young.

The Azmyth platform integrates with various imagery sources, including Mosaic cameras, and allows Vulcan to capture accurate, reliable data from images without the need to take manual measurements while walking from pole to pole. Vulcan Line Tools has developed the capability to quickly and efficiently measure and assess pole infrastructure using a combination of photogrammetry and their own high-resolution captures with the Mosaic X camera system.

Zac Young mentioned that the software enables them to perform measurements like attachment heights, span angles, and pole distances—all crucial for utility companies that need to install fiber cables, electric lines, and other infrastructure without physically visiting each pole. Zac highlights that previously, a two-person crew would walk to each pole and use manual tools to gather data, costing “hundreds of dollars per pole.” With Azmyth, Vulcan can perform the same tasks remotely, “doing thousands of poles in a week” rather than the industry norm of a few hundred.

Red, Yellow, Green

The end result is a colorful map Vulcan Line Tools is calling “Red, Yellow, Green.”

- Red = expensive power pole to attach to, meaning there is power make ready required

- Yellow = moderately expensive, meaning there is communication make ready required.

- Green = inexpensive power pole to attach to, meaning there is no make ready required

Red, yellow, or green is based on how much spacing is on the pole for new fiber, a very hot market right now with the amount of government funding to get high-speed internet to rural parts of the country.

Why It’s Important

The importance of wooden utility pole inspections cannot be overstated. These poles are vital components of the power and communication infrastructure, supporting electric lines, fiber cables, and other services. Failure to regularly inspect and manage poles could lead to safety hazards, service disruptions, and costly repairs. Traditional pole inspection methods are labor-intensive and expensive, requiring field crews to visit each pole physically.

Vulcan Line Tools has revolutionized this process by creating a platform that allows for remote inspections. With their Azmyth software, utility companies can collect accurate, reliable data without the need for extensive fieldwork. This leads to:

Increased Efficiency

Utility companies can assess thousands of poles in a matter of days, reducing the time and manpower needed for large-scale inspections.

Cost Savings

Remote data collection and analysis save utility companies substantial amounts of money, cutting down on labor costs and reducing delays caused by manual inspections.

Improved Accuracy

The platform provides highly precise measurements, with margins of error as low as 2.5 inches, ensuring that decisions related to infrastructure are based on accurate, up-to-date data.

What It Means for Vulcan Line Tools and Their Customers

For Vulcan Line Tools, the development of the Azmyth platform and its integration with high-resolution imagery has allowed them to scale their operations significantly. As Zac mentioned, they have been able to offer more competitive rates compared to their competitors by offering faster, cheaper services.

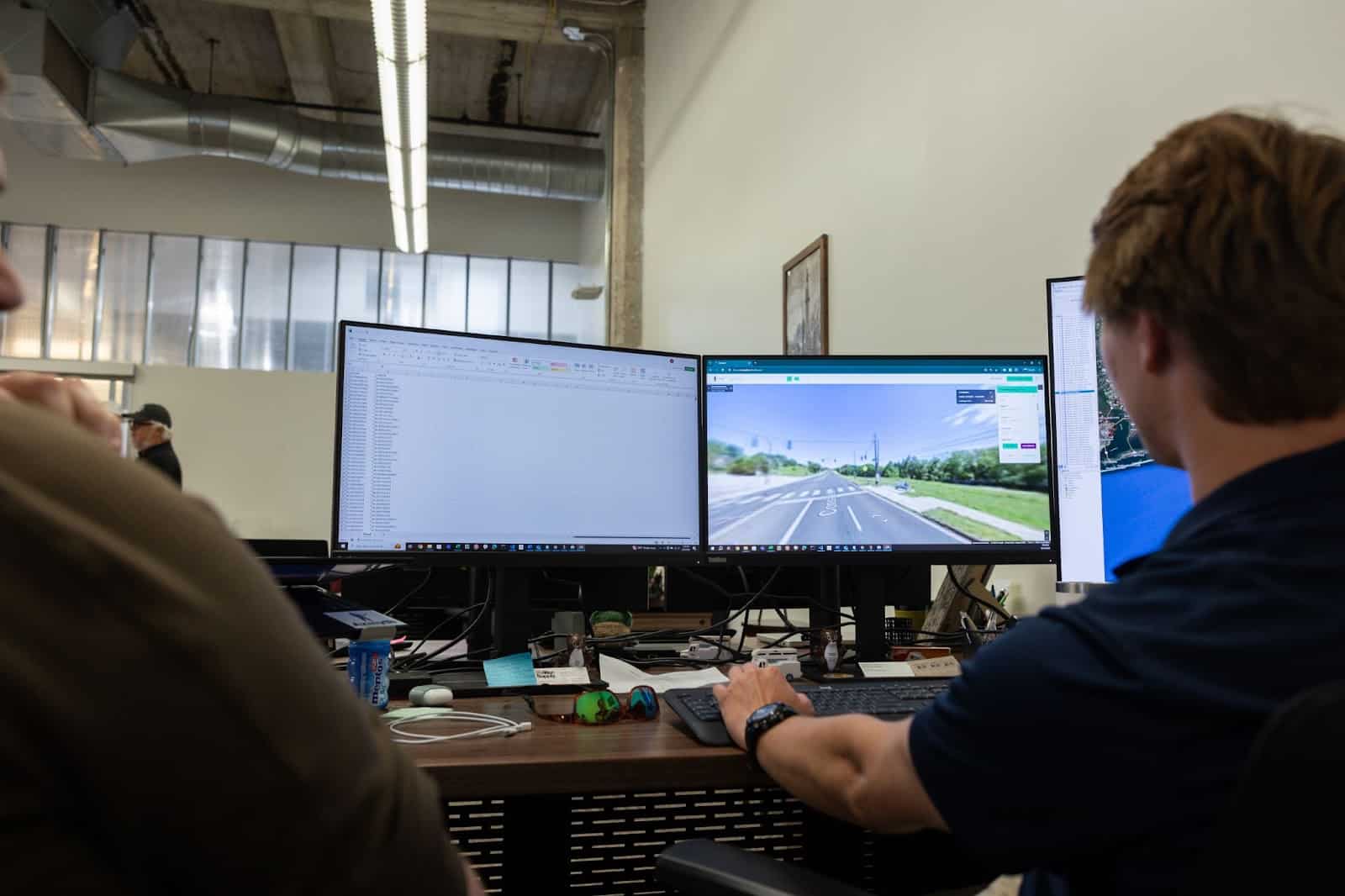

Instead of sending crews to walk between poles for months manually, they can now capture data at highway speeds using the Mosaic Camera System, process thousands of poles per week in a matter of hours, and take precise measurements without leaving the office. Accuracy is crucial when working on electric distribution infrastructure of any kind, and the quality of the Mosaic X ensures that their measurements are extremely high quality.

This innovation is a game changer for their customers. By using Azmyth, these companies can quickly determine attachment viability during the planning phase of their projects. Additionally, the software’s accuracy minimizes the risk of mistakes, such as incorrect pole placements or fiber attachments at dangerous heights.

The ability to remotely collect and analyze data makes Vulcan Line Tools a crucial partner for any company needing fast, reliable, and affordable pole data.

Integration and Usage

“The integration process was painless. We simply needed to grow familiar with the camera and perform a couple of test runs with it on the car before we were ready to use it in the field. All of this took only a day or two.”

The Mosaic X camera system was integrated into Vulcan’s workflow, enabling them to capture imagery across multiple states while maintaining operational flexibility. The ability to collect high-quality data at scale has allowed Vulcan to optimize their inspection process, including:

- Attachment Heights: Accurate positioning and assessment of attachments on utility poles.

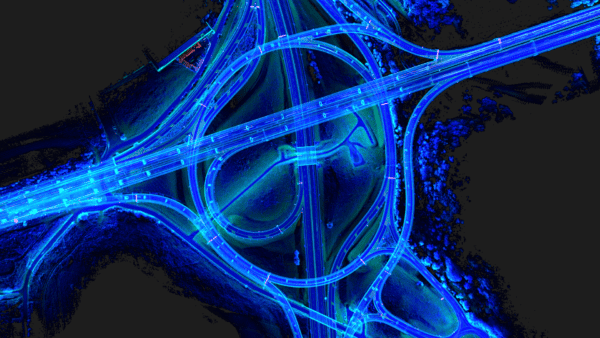

- Span Angles: Measuring the angles between poles for better infrastructure planning.

- Midspan Clearances: Ensuring adequate clearance from the bottom of a line to the ground at the midpoint between power poles.

- Anchor Lead Lengths: Precise measurements of anchor distances for secure installations.

- Efficient Data Processing: Outputting thousands of poles weekly for comprehensive analysis.

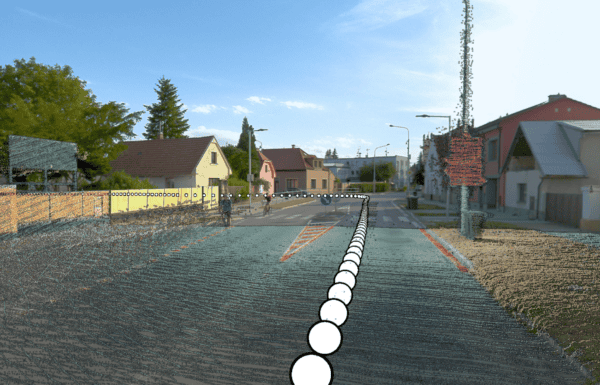

“Every one of these dots is a picture,” Young explained, referring to a project where “this was 39 miles, so this was 7,000 pictures we took,” showcasing the system’s capacity for extensive data coverage.

“We’ve been running like crazy over here, too, especially because of the camera! As we scale, our biggest hurdle is finding enough workers to fulfill demand.”

A recent contract has brought the crew there to collect imagery on all distribution poles in Brownsville, TX. This data will be used to determine the possibility of new fiber cable installations.

Enhanced Accuracy, Efficiency, and Imagery Quality

“The data is high quality, and since we can collect it so quickly, it provides our customers with up-to-date and expansive data that is otherwise quite hard to come by. For this reason, it is quite reliable for repeated use until some major changes are made to the poles in that area, like a major storm, new developments, etc. Even then, the most basic use of the data, which is locating the precise coordinates of each pole in an area, is still applicable.”

Integrating the Mosaic X camera system and Azmyth software has transformed Vulcan Line Tools’ ability to collect and analyze data on utility poles. By using high-resolution imagery, Vulcan captures thousands of poles weekly, cutting inspection times from months to weeks and reducing labor costs significantly. Zac Young shared,

“Previously, a two-man team would walk to each pole, costing hundreds of dollars per pole. Now, we can capture thousands of poles in a week. To date, we’ve processed tens of thousands of poles through our platform.“

The camera’s exceptional image quality has been crucial for accurate data analysis within Azmyth, leading to improved decision-making for utility companies. Accurate imagery ensures that necessary upgrades and repairs are correctly identified and prioritized.

In just two months, Vulcan collected over 2,600 miles of imagery across Florida, Texas, Alabama, and Ohio, with more expansion planned. This scalability, combined with cost savings from the efficiency gains, has allowed Vulcan to deliver precise measurements, consistently accurate within 2.5 inches. As Young noted,

“You’re now getting a 5,000-pole city for around $30,000 when before it would’ve been well over $100,000. And it’s being done in weeks rather than months.”

These savings are passed on to customers, further enhancing Vulcan’s market competitiveness.

Software-Driven Insights:

Vulcan Line Tools’ inhouse built software (Azmyth) analyzes and takes measurements for:

- Attachment heights

- Span angles

- Span lengths

- Midspan Clearances

- Anchor Lead Lengths

All of these support tasks to make ready engineering, pole loading analysis, and field data collection.

Azmyth enables accurate measurements, supporting critical tasks like pole loading analysis and make-ready engineering, all without leaving the desk. A recent accuracy test showed a 2.5-inch margin of error, underscoring the reliability and precision of their system.

Final Customer Words

Zac Young emphasized the positive experience of working with Mosaic, stating:

“Working with Mosaic has been a great experience. They’ve been responsive and supportive as we integrate their technology into our projects.

The ability to drive at highway speeds while capturing high-quality images has been a game-changer for us and a marked improvement from our last camera. We consider the exceptional quality of our imagery and efficiency of our collection process as proof-of-concept for Mosaic’s products and solutions.”

Conclusion

By adopting the Mosaic X camera system, Vulcan Line Tools has greatly enhanced their efficiency, reduced costs, and delivered higher-quality services. The camera’s ability to quickly capture precise, high-resolution images has been transformative for the company. With the support of Mosaic, Vulcan is poised to continue scaling its operations and further streamline the inspection and asset management of utility poles across the country.

For more information about Vulcan Line Tools: visit their website vulcanlinetools.com

Looking to get in touch with us here at Mosaic? Contact us below 👇