The need for speed and high-definition delivered in one solution. Learn more about this case study of an electrical grid inspection

Who is Dymaxion

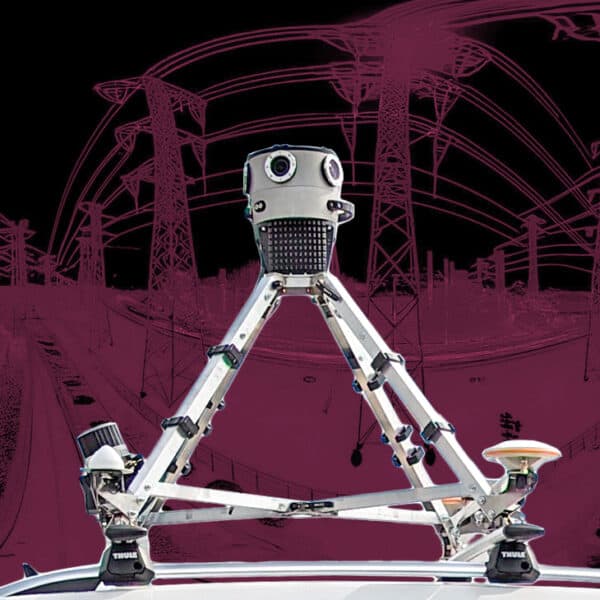

Another business that joined the club of our customers who Mosaic has helped push the boundaries of what they expected from their mobile mapping project is Dymaxion S.A.S. Today, we are going to look closer at two mobile surveying projects in which Mosaic 51 proved again to be designed to handle a whole variety of challenges, including the requirements for high-definition 360° imaging specific for electrical grid analysis, as well as extreme weather conditions.

Dymaxion SAS is a Colombian engineering company founded in 2011, focused on applying mobile mapping (including UAV), photogrammetry, atmospheric sampling and remote sensing (LiDAR) technologies to optimize data capture times and to improve design results for the road infrastructure, power lines, oil and gas, mining sector etc.

Until recently, the data capture needs of their projects could be perfectly covered by LiDAR surveying (creating geo-referenced point clouds) and photogrammetry (capturing and editing 3D spatial objects from high-definition images).

The situation was about to change with a challenging 3-year project Dymaxion tendered for and won. We spoke with the CEO, Gustavo Guevara, about accepting the challenges and finding solutions.

Challenge nr. 1: Analyzing the electrical grid on nearly 30,000 kilometers

An electrical distribution company commissioned Dymaxion to map and collect detailed information about the condition of the power lines over a length of almost 30,000 kilometers.

“This is really a large scope mobile mapping project. We were about to collect data every day for around 3 years. We had to design a backup solution integrating different technologies to match the data capture to the specifics of the grid analysis.”

Gustavo Guevara, Dymaxion s.a.s. CEO

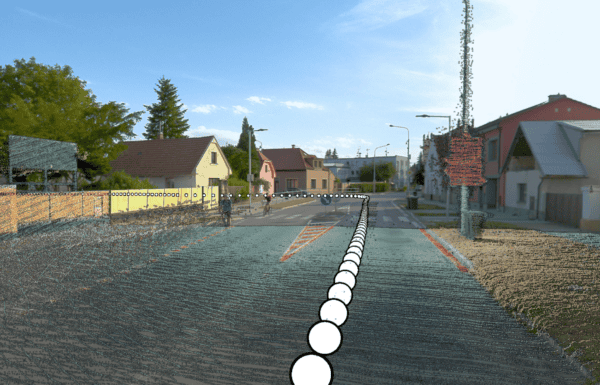

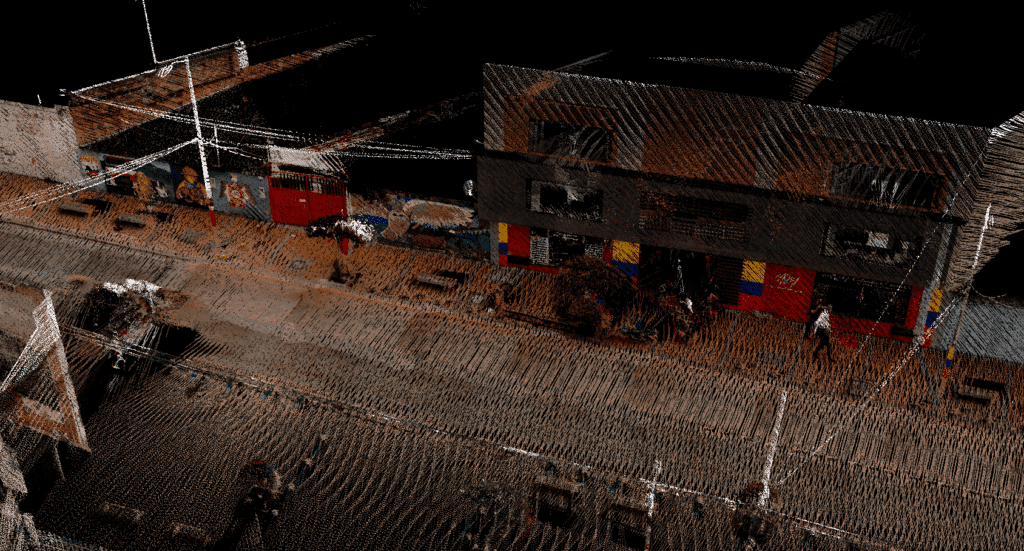

First, it was necessary to make sure enough point data can be collected using a vehicle mounted LiDAR for 3D representation of the grid network. But to be able to evaluate the condition of the grid, more detailed visual representation of the network is necessary. This is when it came to address the need to colorize the point cloud.

“What the client needed was a real picture of the network, whether it is in good or bad condition. So, we needed a high-definition photograph of every asset, of every single pole, of all the wires.”

Digital twins in the utilities

The importance of putting color to the point cloud in the utilities is enormous.

“We had to make sure the team involved in the asset inspection can zoom in and detect if there is damage, for example on the transformer or on the connectors with the wiring or on any part of the poles, like corrosion for example. So basically, you need to have digital twins of all the network components at hand to know which parts need to be replaced. You also need to know the exact condition of the electrical grid to be able to plan the maintenance efficiently and strategically.”

Looking for the right 360° camera for electrical grid analysis

Choosing the right 360° camera for your mobile mapping project is a complex process and a lot needs to be considered. Apart from the price, all the specifics of the mobile mapping project need to be taken into account so that the 360° camera you finally choose meets the requirements of the project in terms of data accuracy, speed of data collection, data post-processing, etc.

“When you are about to invest in a valuable camera, you need to make sure you make the right decision. This can be difficult as you usually don’t have the option to try the camera.”

What Dymaxion was looking for, for the electrical grid analysis project was a 360° camera that can be integrated with LiDAR, (For grid analysis, the use of photogrammetry alone could be tricky because of the natural obstacles to the light such as trees.)

Another key element in the decision making process was the ability of the camera to take really high-definition pictures with a lot of details specific for the grid network analysis to provide their client with very good proof about the condition of all the network components. The Mosaic 51 camera system with six 12K resolution sensors made it the ideal candidate.

“Of course we found a wide range of different versions of 360° cameras on-line. However, a detailed comparison of Mosaic 51 with another solution we found on their website gave us a clear idea about the details that can be captured by Mosaic 51 and that brought a lot of our attention to this 360° camera.”

Integrating Mosaic 51 with LiDAR

After receiving the camera and performing initial testing, it came to integrating Mosaic 51 with LiDAR.

“There was a lot of development ahead as Mosaic 51 is not a LiDAR integrated solution.” (The solution fully integrated with RIEGL LiDAR is Mosaic X, but that system was not available back then yet.) “However, the time we spent with the integration helped us a lot in the way we understood how this merge was going to work.“

With the amount of data to be captured every day, Dymaxion was sure to be looking for an easy and automated solution to match the images with the point cloud. All data captured by Mosaic devices is non-vendor-locked, which allowed Dymaxion to choose a software that allows additional calibration in post-processing.

“There was a lot of work to be done but the outcome is really great. We have a very good visualization for our client.”

While it is common knowledge that rolling shutter sensors require additional effort for colorizing point clouds (as opposed to global shutter sensors), Dymaxion proved that it can be done!

The benefits of non-vendor-locked data captured by Mosaic

Apart from the greater flexibility in how the data can be analyzed and visualized, which allowed Dymaxion to address the issues with the calibration in the post-processing, when data is not locked to a particular vendor’s software, it also enhances the cost efficiency.

“One of our previous cameras with a built-in software entails relatively high software update and license renewal costs, especially because of the different currencies. So, it is great that with Mosaic, we can make our own solution for post-processing without having to renew a software contract year after year. “

Challenge nr. 2: Mosaic 51 on the road again – The highest possible accuracy road inspection

Shortly after Mosaic 51 settled in at Dymaxion during the grid analysis project, they decided to use its benefits for another mobile surveying challenge – road inspection. Several important road projects are currently progressing in Colombia and Dymaxion got involved in which there will be major road expansion of a motorway.

Long stretches of motorways in Colombia were built with only two lanes because the construction project was terminated after the first stage of the construction. Their widening is now about to be taken care of by a new contractor. But to be able to pick up where someone else left off, the new contractor needed to know the exact condition of the construction, the inventory and state of all the assets including the road surface, the railings along the transport routes, the road signs, information about surrounding terrain, etc.

Road inspection in extreme weather conditions

The mobile surveying project was running in northern Colombia, where the temperature during the day can easily go over 35 C° and the scope of the mobile surveying required all-day long data capture.

“The temperature on the car rooftop in the daytime can easily go over 40 degrees. We were a little worried about the functioning of the camera in these extreme weather conditions, but we’d drive 300-400 km/a day in this very hot weather and the camera was working perfectly. “

This is a good illustration of what Mosaic‘s 51 robust industrial frame was designed for and what our customers benefit from when it comes to mobile surveying in difficult weather conditions.

(updated March 2024)

The trees that help to keep the temperature lower for the drivers are unfortunately an obstacle at the same time to the data capture using only a UAV LiDAR so Dymaxion decided to combine aerial LiDAR data with vehicle-based LiDAR and Mosaic 51 360° imaging to make sure the clearest possible and geo-referenced picture of the inventory will be provided to the client. While for smaller inventory mapping projects it is perfect enough to just make use of the 12K resolution of Mosaic 51 360° camera, in this case, precisely geo-referenced LiDAR data is needed as a background for further construction.

The importance of a good timestamp

When geospatial data is acquired simultaneously by multiple sensors (in this case by the Mosaic 51 360° camera, the built-in GNSS receiver, and an IMU to capture the motion data) precise timestamps ensure that these measurements are correctly synchronized with each other.

“This part was a little bit complicated, to align the timestamps from the IMU and the GNSS with the nanosecond the image was taken. We didn’t have an exact match but using six control points over the road in the post–processing actually did the job.”

Being aware that the data post–processing can be demanding; Mosaic has been developing and fine-tuning an automated solution for geo-referencing (stitching) the images using a calibration template our clients can soon be looking forward to. (Stay tuned).

Maximum efficiency with dynamic approach

As the name of the company suggests, Dymaxion is another one of our customers who is not afraid to grow with big projects and is ready to find a solution for any challenge on the way. At the same time, they can rely on the best-in-class mobile mapping solution, Mosaic 51 360° camera that can withstand harsh climatic conditions and can operate all day without the speed of data capture, the accuracy of data output, or the high-resolution of the image important for grid analysis being affected.

Today Mosaic already has a mobile surveying solution for advanced photogrammetry, fully integrated with Riegl laser scanners, Mosaic X. At the time when Dymaxion was looking for a 360° mobile mapping solution this was not yet the case yet. However, thanks to a diligent integration and post-processing effort they were able to integrate high-definition data captured by Mosaic 51 to the point cloud allowing Dymaxion to not only provide image-like and geo-referenced data to the client but most importantly, to build trust, which we believe to be the key to successful projects.