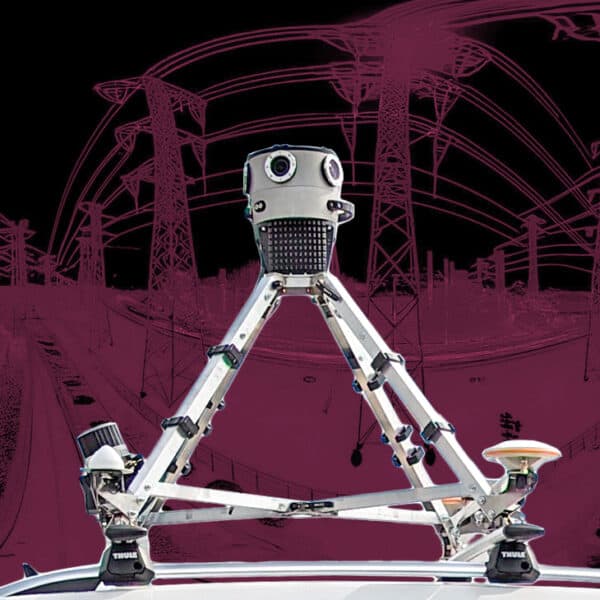

We’re not making cameras. We’re making extremely high-quality data capture and precision measurement instruments.

As I spoke about in Part 1 of this ‘mini-series on technology, design, and invention, the design process for Mosaic cameras is much more complicated than many believe. There can be various iterations along the way, always with the intention of creating the best product with the available mapping technology.

So now that you’ve read Part 1 and you have a better handle on how technology, design, and inventions work together to make Mosaic cameras, let’s answer the question I get so often about our cameras:

What makes Mosaic cameras and their technology so good?

Our engineering team carefully considered and designed each part of our Mosaic 360º mobile mapping cameras to offer customers the best possible experience and outputs. We have been determined to build the right tool for the job – particularly the jobs surrounding the geospatial, mapping, and surveying industries.

Hardware is hard. Cameras are harder.

Mosaic Camera Technologies

Designing a camera is very difficult. They are fantastically complex devices. Building them at scale and ensuring they work is also very difficult. We’ve spent the last couple of years doing these things, and it has been a tremendously long process. But now that we have so many cameras in the wild, I can say that it has been successful. In this article, I’d like to walk you through a few points about what we have built and why they are the best solution on the market right now.

Mosaic’s Image Sensors

We are using Sony image sensors, which are highly regarded on the market. Many of the world’s best cameras use them.

The Mosaic 51 has rolling shutter sensors, which are very good in terms of dynamic range and noise. For our mobile mapping and surveying customers who want to perform street-level data collection, the Mosaic 51 proves to be an exceptional, well-rounded product that checks all of the boxes.

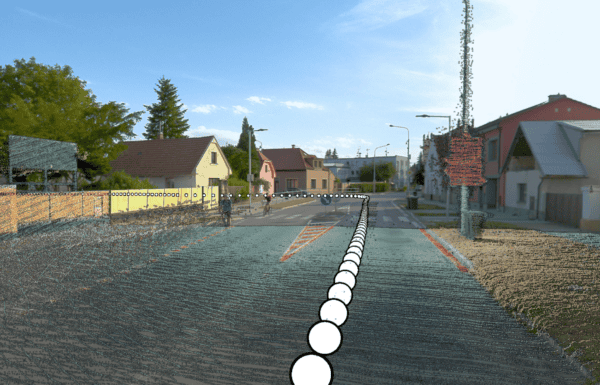

The Mosaic X has global shutter sensors, which offer exceptional performance (at a higher cost) and images. These images provide a simple workflow for coloring point clouds or building textured mesh 3d models using photogrammetry.

The Mosaic Viking, our “no holds barred” camera, has large APS-C sized 31-megapixel global shutter sensors. It offers a tremendous 22K resolution stitched 360-degree panoramic image, or 186 megapixels of 12-bit uncompressed RAW data at 5FPS (that’s 930MP per second!)

Mosaic’s Lenses

We take optics incredibly seriously. It doesn’t matter how good your image sensor is if you don’t have a lens, focusing the light correctly across the entire sensor. We also need to be sure that our lenses follow a geometric lens model. This way, we can calibrate and map correctly, according to a mathematical formula, so our customers can remap these pixels later on for various tasks.

While we say we are building a “camera,” it is, in fact, a precisely calibrated instrument that is the basis of many other highly technical operations. These include image stitching, coloring point clouds, and photogrammetry.

So, our lenses need to be fantastic – every single one of them. And we inspect and calibrate every single one! One of our deliverables to our customers is a personalized calibration file, particular to their camera. This allows them to work with it later in post-processing tasks such as stitching 360 panos and 360 videos.

Mosaic’s Housing & Frame

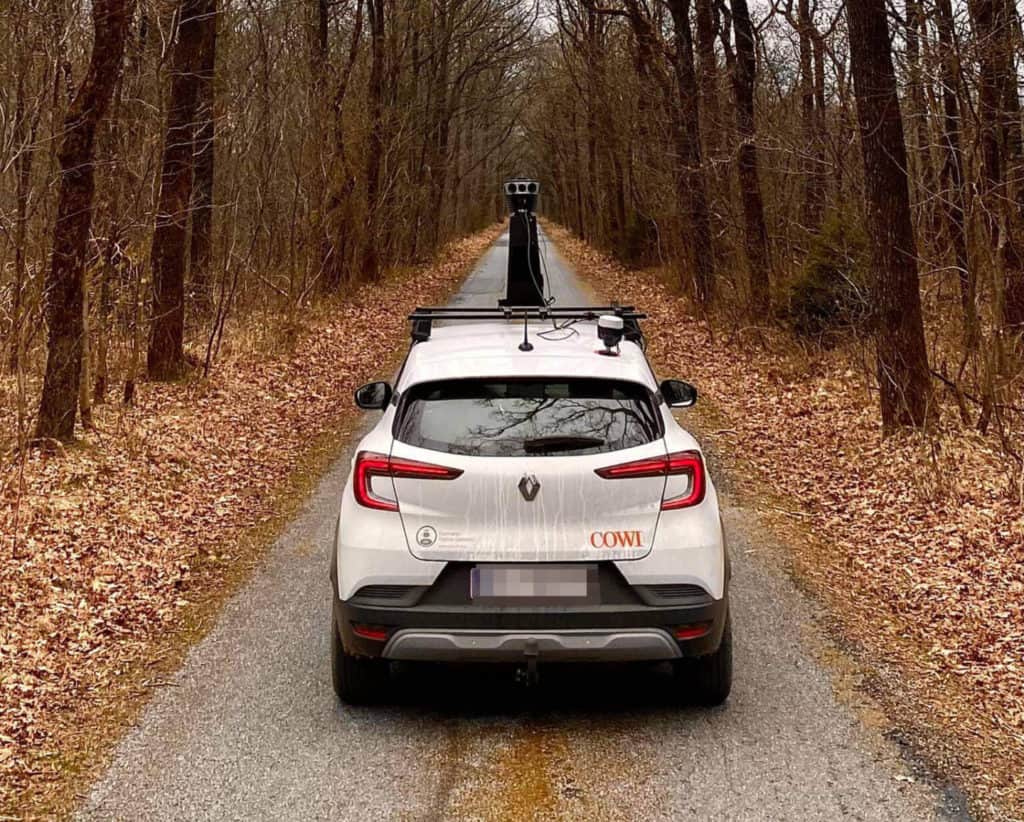

Some cameras are designed for regular people, some are meant for filmmakers, and some are installed in factories. Every type of camera has to be built for a specific type of wear and tear, and it needs to be dependable.

Mobile mapping can be a hot, wet, bumpy and dirty business. These cameras are put on top of cars in any condition: hot, cold, wet, or dusty. We need to be sure that they survive those conditions. The roads might be bumpy, and rocks might hit the lenses.

If the camera is in Jordan’s hot desert or India’s sweltering tropics, it needs to work just as well as anywhere else. This is not an easy task. Inside our camera is a whole computer – it’s small, but it can get hot – as well as the image sensors themselves. We can’t put holes in the camera with fans to cool it off, as you might be able to do with a studio cinema camera.

So, our housing is sealed against the elements. We have scratch-resistant optical glass windows in front of the lenses to protect them from damage. We have a lot of thermal mass, as well as considerable heat sinks on the housing, which is thermally coupled to the hottest parts of the electronics.

Mosaic’s Connectors

All cameras have connectors on them, including ours. Mosaic cameras don’t use consumer-grade connectors, which usually aren’t secure or reliable in the long run. We always use industrial-grade waterproof connectors, which are sure to work.

Mosaic’s Mounting

If you’re putting your camera on a tripod, it is okay to use a ¼” tripod screw. What is the worst that can happen? Nothing, really. If you’re putting a camera that is a few kilos on the roof of a car, you don’t want to gamble everything on the strength of one single screw. Screws have very little shear strength, so if you’re holding two things together with only screws and nothing else, then a hard impact could snap the screws (say, if your car slams on the brakes or hits something).

The camera mounting interface, therefore, has “keys” or notches, which fit into a counterpart hole. These help considerably in resisting shearing forces, as this force will be concentrated on chunks of metal meant for that. This allows the screws to do their job of holding everything together without any danger of breaking.

Mosaic’s Timestamps and Synchronization

The Mosaic camera exposure pulses, synchronization, PPS signal, and anything that has a clock coming into or going out of our camera we calibrate in nanoseconds.

1000 nanoseconds = 1 microsecond

1000 microseconds = 1 millisecond

1000 milliseconds = 1 second

Yes, nanoseconds. That is all.

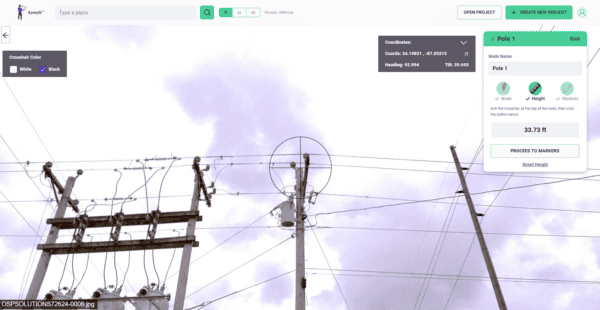

Mosaic’s Auxiliary Port

Of course, our cameras don’t exist in a vacuum. And we don’t even know how customers use our products. Our customers have many other types of devices that they use, and they might want to connect everything. External GNSS, IMU, LiDAR, and so on – these devices need to synchronize and talk to each other. Our auxiliary port has a standard rs-232 interface, and we have made it as easy as possible for our customers to use.

Mosaic’s Standalone Device Models

The Mosaic 51 and Mosaic X are each standalone units, meaning they have a built-in CPU and GPU (e.g., computers). This means the data collector does not need to also buy, care for, or maintain a computer within the vehicle during data collection.

Both models are fully self-sustaining and only require an external battery pack.

They have a hot-swappable SSD storage unit that can store all of the images captured for a full day of data capture.

So what makes Mosaic the best in the field?

As I spoke about in the previous article about technology, design, and invention, you need to work with the best and latest technology and combine it to fix the current challenges users face.

We have taken into consideration the many issues that we’ve stored in the back of our minds for years from members of the geospatial community:

- Poor quality housing

- Inability to handle the heat

- Susceptibility of fogging up or allowing water into the camera

- Inability to remain attached to the roof on bumpy roads or when braking sharply

- Easily-scratched lenses which are costly to replace

- Difficulty in using devices

- Heavy and, therefore, dangerous devices requiring multiple operators

Nothing is perfect, but currently, there is no better solution on the market, and we’re not speaking without evidence.

Our approach with your camera, absolute winner. There isn’t any part of the process where we’ve felt that we’re going backwards.

Dan Davis, Catsurveys

Buying this camera was one of the easiest decisions I’ve ever made. On every single metric, the Mosaic 51 beat out the competitors: its image quality is the best.

Pamela Blackmore, Sevier County

If you’re looking for the best mobile mapping cameras on the market, contact us, and we’ll help you find the right tool for your job.