Digital Twin Solutions

You might be more familiar with what are some digital twin solutions and uses than you realize. Movies such as Iron Man, Minority Report, and Star Wars have all presented us with images of 3D replicas of machines, tools, vehicles, and environments. The characters in the movies were able to gain insight and make adjustments to the assets accordingly. And while some Hollywood magic is just that – magic – this one is no longer a magic trick, it’s real.

History of the Digital Twin

While Dr. Michael Grieves, a renowned scientist and research professor at Florida Institute of Technology gets credit for first coining the term ‘digital twin’ in 2002, the timeline traces back slightly longer. Due credit should also be given to David Gelernter, Yale University computer scientist and author of Mirror Worlds in 1991. He is credited with anticipating the concept and implementation of digital twins. Dr. Grieves furthered the understanding as he applied the conceptual model to underlying product lifecycle management.

What is a Digital Twin?

If you take the time to read some of the top articles or watch some of the more popular videos about digital twin solutions and technology, you might come across a whole host of definitions regarding ‘what is a digital twin’ and what it is not.

Each definition offers a slightly different presentation of what a digital twin is and how it is used; each one can be more or less understandable to different people. So we decided to offer you a selection of some of the better ones.

Definition(s) of Digital Twin

- The simplest definition:

“A living entity” - The most comprehensive definition:

“An up-to-date representation of a real asset in operation” MATHLAB - The most simple but most detailed definition:

“…the ability to take a virtual representation of the elements and dynamics of how an IoT device operates and works. It’s more than a blueprint, it’s more than a schematic, it’s not just a picture, it’s a lot more than a pair of glasses, …the ability to take a virtual representation of the elements and dynamics of how an IoT device operates and lives throughout its lifecycle.” Chris O’Connor General Manager and Senior Executive Leader of Internet of Things at IBM - The most scientific definition:

“A Digital Twin is an integrated multiphysics, multiscale, probabilistic simulation of an as-built vehicle or system that uses the best available physical models, sensor updates, fleet history, etc., to mirror the life of its corresponding flying twin.” Nasa 2012 - Our favorite definition:

“the effortless integration of data between a physical and virtual machine in either direction” Fuller and Fan

We hope that at least one of these definitions articulates the incredible power that lies within a digital twin. We’re going to walk you through a few more ‘what a digital twin is and is not’ as there are many misconceptions and misnomers concerning digital twins.

Many companies and many people tend to confuse and misrepresent the sort of technology they are working with. The term ‘digital twin’ often gets thrown around when in reality, it is ‘merely’ a digital model or a digital shadow.

Let’s quickly go through the difference between each of these technologies.

What is the difference between a digital twin and a 3D model?

A 3D (or digital) model: presents a conceptual, detailed design of an asset or process in a digital environment. This is a method of evaluating design options and unique possibilities without having to manufacture the physical objects. These models check for the preparedness and cost-efficiency of a project before the production or construction begins.

In the creation of a 3D model, information is flowing in one direction, from the digital model to the physical object. The model is a 1 to 1 representation of the actual device, containing a significant amount of meta-data.

A 3D model or digital model might later be used within a digital twin if it can be developed with additional detail and can simulate changes for the manufacturing or construction process or for the asset’s management.

What is the difference between a digital twin and digital shadow?

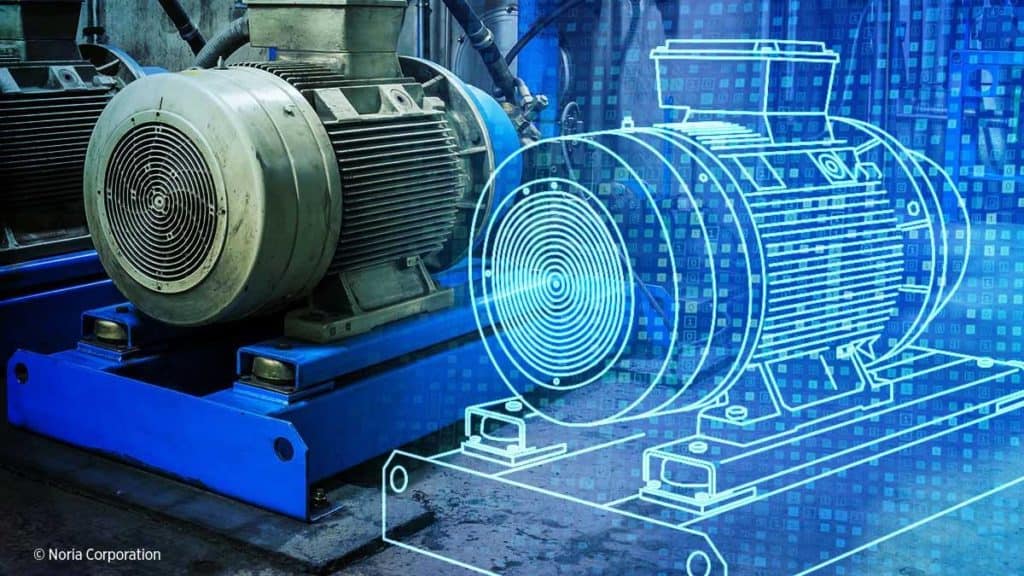

A digital shadow is also a 1 to 1 representation of an actual device in the field.

The use cases for a digital shadow are the opposite of a 3D model. Rather than using a 3D model to design before construction, a digital shadow is receiving the flow of information from the physical world into the digital representation. With this information, future revamps or retrofitting occurs. Any change in the physical object corresponds to an automatic change in the digital model.

Digital shadows can be used to inspect parts or train employees more efficiently. However, it must be noted that while extremely beneficial and effective, the information received from the physical device or process does not lead to updates on that very asset or process. The flow of information is only one-directional.

What is the difference between a digital twin and simulation?

A simulator helps us understand what may happen, while a digital twin helps us understand what is happening (how the design is behaving in real life). Simulators do not integrate real-time data, while digital twins do.

A simulator can analyse thousands of variables to provide diverse answers, while a digital twin focuses on making more accurate predictions of how parts will fare over time. This is because simulations use forecasting methods, predicting the potential situation, while digital twins gather all known data of large-scale projects, processes, and equipment to create a up-to-date, easily understood model of the current situation.

Simulators are utilized for R&D with the aim to find a better design for an asset. The digital twin is used for design-execute-change-decommission in real-time.

Of course simulators and simulations are an intricate part of digital twins; standalone simulations can combine to form digital twins for a better understanding of complex situations and environments involving infrastructure, people, equipment, and cars.

Digital Twin Solutions and Use Cases

Digital twins, if done correctly, will influence how the design, build and operations of a device are constructed in a single life cycle. This has near-limitless applications and solutions in our ever-digitalized world. Some of these digital twin solutions might be quite obvious thanks to TV shows and movies which show futuristic visions of digital twins and others may not be as obvious, but are just as transformative and impactful.

Manufacturing

- Virtual prototyping, R&D, designing, testing (jet engines, automobiles, tunnels, dams)

- Can the product perform and at the quality necessary in its environment

- Deliver products more rapidly

- Deliver products more safely

- Troubleshooting equipment and processes remotely

- Allows teams to collaborate around the world

- Allows companies to find the best talent, no matter where they may be

- Predict issues sooner

- Increases connectivity and feedback between devices

- Improves performance and reliability

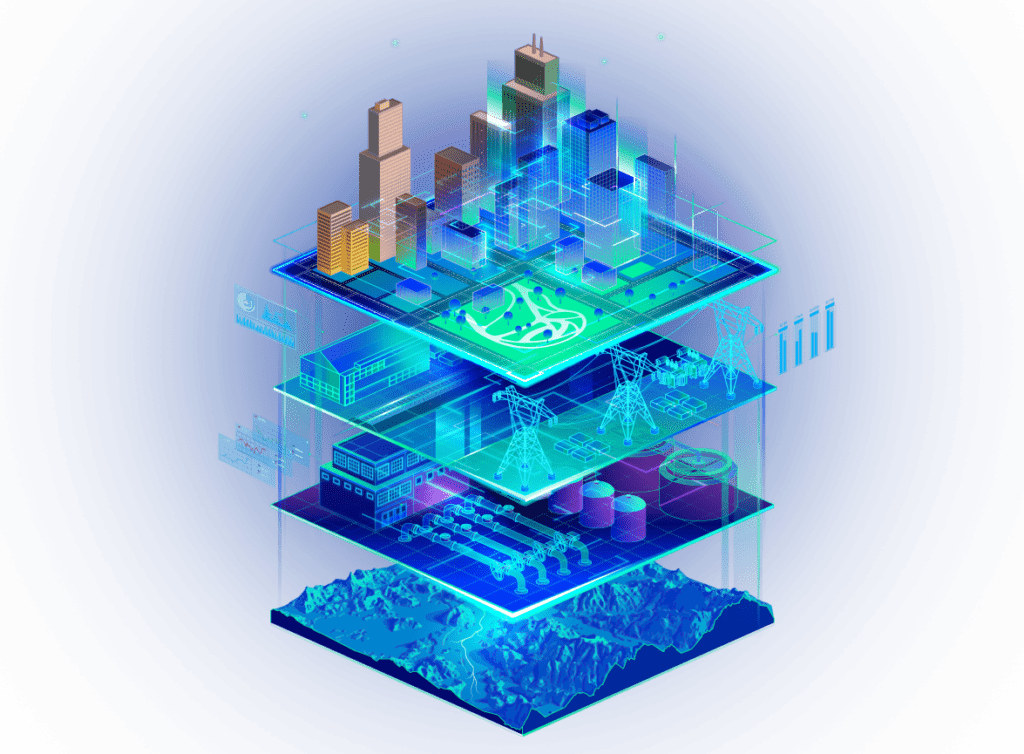

Smart Cities development:

- Design and plan cities of the future

- Monitor current situations to look for cost-saving, energy-saving opportunities

- Future development and creation of IoT and more advanced AI algorithms

- Offer feedback and information for current smart cities

- Provide insight for future smart cities

- Understand and reach to utility use and distribution

Smart Cities development

- Design and plan cities of the future

- Monitor current situations to look for cost-saving, energy-saving opportunities

- Future development and creation of IoT and more advanced AI algorithms

- Offer feedback and information for current smart cities

- Provide insight for future smart cities

- Understand and reach to utility use and distribution

Supply chain

- Evaluate devices and tools involved in the supply chain

- Analyze the efficiency of the individual parts of the supply chain

- React quickly to inefficient or poor quality products

- Increase understanding of any breakdown within the chain

- Establish best practices for future logistical operations

- Predict the performance of packing materials

- Enhance shipment protection

- Optimize warehouse design and operational performance

Healthcare

- Simulation of the effects of drugs

- Planning and performing surgical procedures

- Specified environments gives those in the healthcare profession the ability to look for future developments and uses

- Make smarter predictions and decisions

- Current and ongoing care and treatment

- Predictive maintenance and ongoing repair of medical equipment

- Improving personalized care

- (future use) digital twin of a human body with real-time analysis

Real-life Examples of Digital Twin Solutions at Work

1. Medical devices

As of 2018, the leading cause of death in the United States was heart disease, according to the CDC. Hearts are composed of specific and unique physiologies, meaning that each person in the world has a unique combination of these.

Miniaturized sensors that monitor patients will permit their heart function to be simulated in a variety of circumstances, including walking, sleeping and climbing stairs, rather than just for the brief period when a patient is undergoing clinical examination.

Digital twins would draw data from a broader suite of sensors, and for longer.

Technologies to be adapted include health apps on smartphones and fitness trackers, wearable ultrasound scanners, or yet-to-be-created wearables capable of conducting heart scans while still being washable.

Currently being investigated and researched by ECHOES at University Hospitals Leuven in Belgium in collaboration with ANSYS (a computer-simulation company) and GE (jet engines and medical device manufacturer). Similar equipment gives hope and motivation to these researches, such as a project called EurValve, which has developed a system which is helping doctors treat people with heart-valve diseases. It allows all of the data from doctors, the hospitals and patients (going about their normal routines) to be uploaded and analyzed to predict the outcome of heart-valve-replacement surgery.

2. Supply chain management

Remember, digital twins are not just for physical assets. Microsoft’s Azure Digital Twins illustrated an incredibly complex solution for supply chains in this video which we highly recommend watching. They showcase how a supply chain for a clothing manufacturer can create a replication of their entire supply chain, including every assembly line, every machine, and every logistical element involved.

Then through the use of multiple sensors, they can collect up-to-data about the current status of those elements and analyze the data if they notice that there is a problem along the supply chain line.

Based on what they find, they are then able to make decisions about whether to continue using a particular machine or whether to pause it, repair it, or stop using it all together. With this decision making power, they are able to ensure that the same problem will not reproduce itself in the future and that they can recover the highest quality and efficiency possible going forward.

2. Wind turbine

Energy creation and the assets and processes involved can also utilize and benefit from digital twin solutions. Murli Mohan Srinivas – Head of Global Automotive & Discrete MFG, Global PLM Practice, ATOS, explains how important digital twins are when dealing with wind turbines.

Wind turbines are used across multiple locations such as on shore, off shore, cold climates, hot climates, enduring different types of weather and varying degrees of humidity. All of these factors play an enormous role in the effectiveness and lifespan of a wind turbine.

By using a digital twin of a wind turbine, engineers are able to look at historical data of a particular wind turbine to understand what factors play the most significant roles in the longevity of the whole wind turbine or particular parts.

Other factors such as past and current weather patterns can be used to make predictive models and combined with AI and ML, predict failures, inventory necessities and power outages.

3. Self-driving cars

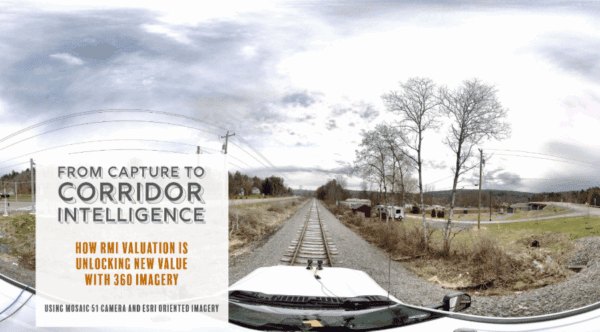

As previously discussed here in our Mosaic ‘Insights’, self-driving cars have a multitude of benefits for society; safety being one of them. This was even one of the motivating factors for Mosaic CEO Jeffrey Martin to step into the world of 360-degree mobile mapping.

In order for self-driving cars to be able to see and respond as humans do while behind the wheel, they need to have a visual representation of their surrounding environments. This is exactly what a digital twin offers.

As characteristics and features in the car’s environment change (new road signs, changes in the direction of a street, a new speed limit) the digital twin can react and alert the car to the changes.

4. Offices and facilities

The physical spaces and environments in which we work and operate can also benefit from digital twins. IBM’s own Watson Center has a digital twin of its office workspace. The center can recalibrate the working environment of its employees based on comfort, efficiency and the environmental or economic impact.

Another example of this is with Carl’s Jr. and Hardee’s Restaurants. A spokesman stated:

“The new VR and Digital Twin technology were tested at a recent event for Hardee’s. With these technologies, more than five distinct layouts, 10 equipment changes, and thousands of store-related data were added to the simulation and tested to see their effect on business operations.”

Simio.com

5. Smart Cities

We don’t want to leave out one of the most popular digital twin solutions. But this use case deserves a whole article on its own, so stay tuned for the next installment from Mosaic’s insights to learn all about Smart Cities, what’s currently happening now and what’s to come; AND how Mosaic is leading the way in Smart City data capture.

Technologies Facilitating the Creation and Use of Digital Twin Solutions

Sometimes it is really quite staggering when we look at the advances humankind had made in just the first 20 years of the 21st century. The internet has become the primary form of data sharing and communication. We can communicate with our homes, our cars, and now nearly any other device and process in our environments.

How to Create Digital Twin Solutions

As we saw earlier, a digital twin is more than a 3D model, it is more than a digital shadow and more than a simulation. But all of those DO play a part in the creation and maintenance of a digital twin.

And while this is by no means an easy process, considering all of the extremely advanced technologies that are required to facilitate all of this, the idea behind how to create and maintain a digital twin is fairly easy to understand .

- Create a digital (3D) model of a device, asset, or process.

- Collect and maintain up-to-date information of the asset in question to build context

- Apply cognitive insights and apply changes to the physical device or process based on the data

Technologies facilitating the creation and use of digital twins

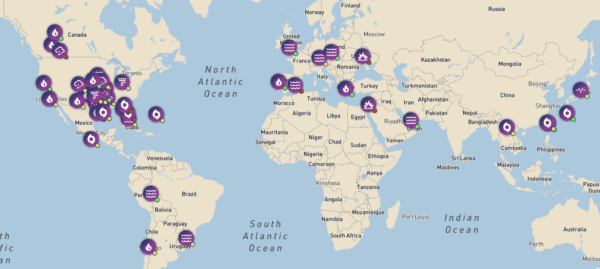

Most of the technologies necessary for creating and using a digital twin can be summed up in letters: IoT, ML and AI, plus a few more such as cloud computing, edge computing, and big data. We do not wish to ignore the importance of any of these incredible technologies, however for our sake here at Mosaic, we wish to focus on what we know best – image data and sensors collected with our cameras built for mobile mapping.

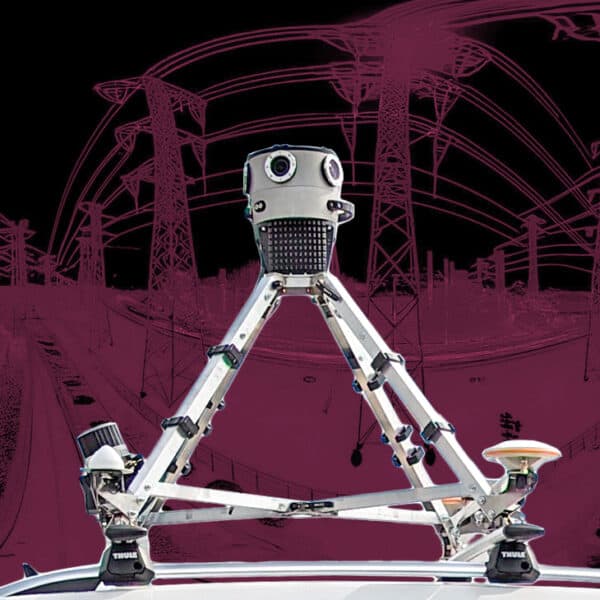

Why Mobile Mapping is the Foundation of Digital Twin Creation

Mobile mapping offers many advantages over other forms of data collection. Mobile mapping devices, which are a combination of sensors including cameras, GNSS, GIS, etc., are just that – mobile. They offer a much friendlier way to gather data.

Here’s just a few of the advantages:

- Efficiency: mobile mapping reduces the number of people needed to collect data, from a whole team of surveyors to a driver

- Speed: rather than spending days or weeks using traditional surveying techniques in fixed locations, mobile mapping can travel at normal road speeds, collecting all of the image data in a fraction of the time

- Scalability: with efficient and speedy data capture, companies with mobile mapping technology can scale their businesses at a might higher rate than their competitors

- Safety and security: mobile mapping offers safety to the workers who are conducting the surveying, as well as comfort when having to collect data in extreme conditions

Thanks to the advancement in the quality of imagery available with Mosaic cameras, we are able to offer our customers the highest quality resolution 360 degree images, captured by the most robust cameras on the market.

Our Mosaic 51 camera is the gold standard in mobile mapping. With a built-in computer, the camera is super mobile and portable, able to be placed on cars, trains, ATVs and other land rovers, as well as strapped to a hiker and taken into extreme conditions off-road.

With six 12-megapixel images sensors and 12K resolution, you can’t find a better camera for collecting high-quality data with ease and at a much reduced cost to traditional mobile mapping and photogrammetry solutions.

And if you thought the Mosaic 51 was impressive, then check out the Mosaic Viking, which is taking image quality to a whole new level. This monster of a camera offers a total resolution of 160MP across six 31MP image sensors. This camera was built to quickly, easily, and accurately collect all image data of its surroundings to help companies and governments construct digital twins of large areas.

The Mosaic Viking is set to revolutionize how digital twins are created and how effective they can be. Stay tuned for how digital twins will be affecting the creation and use of Smart Cities in our next insightful article.

Subscribe to our newsletter below to stay up-to-date on all of the latest news from Mosaic.